Centrifugal Separation Equipment

Cream from milk. Sand from gravel. Oil from water. Pigment from paint. B&P Littleford is a centrifugal separator manufacturer for many types of industries.

Only by undergoing precise separation can thousands of products used by millions of people every day reach their full potential. B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications.

B&P Littleford’s horizontal and vertical centrifugal separation equipment is expertly engineered, precisely manufactured, and rigidly tested to effectively and efficiently separate liquids from solids, liquids from other liquids, and gases from solids.

What is a centrifugal separator?

Centrifugal separator machines use gravity and mechanical means to separate compounds. Centrifugal separators can separate:

- Liquid-liquid mixtures

- Solid-liquid suspensions

- Gas/liquid-solid mixtures

- Other particles by specific gravity

Centrifugal separator machines feature an inlet, outlet, and separator. The liquid-solid, solid-liquid, or gas-solid mixture is pumped into the separator. The separator creates a spinning vortex, which filters solids from liquids.

The separated solids collect at the bottom of the separator and discarded. High-density liquid, such as water, flows out of the separator. Low-density components, like oil, remains inside the centrifugal separation machine.

Centrifuge Separator Manufacturer

B&P Littleford is a centrifugal separator manufacturer and we supply the ideal centrifugal separation equipment for your most demanding applications.

B & P Littleford’s durable, reliable centrifugal separation equipment is ideal for a wide variety of industrial uses:

- Environmental processes

- Plastic manufacturing

- Chemical purification

- Mineral and ore production

- Pharmaceutical manufacturing

- Biotechnology

- Food and beverage production

- Processing sugar

- Making fruit and vegetable juice

- Refining vegetable oils

- Producing wine and beer

- Purifying mineral fuel and lubricating oils

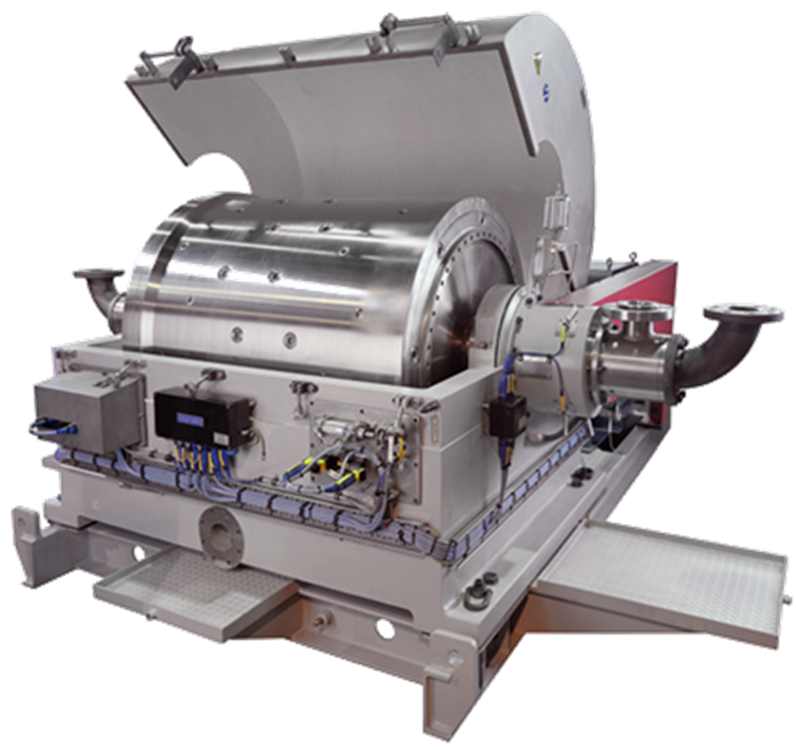

Podbielniak® Contactor (POD®)

B&P’s Podbielniak® Contactor (POD®) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. The two main functions of this machine are liquid-liquid separation and the liquid-liquid extraction process through counter-current flow.

B&P’s Podbielniak® Contactor (POD®):

- Reliable: POD® has been in service for more than 60 years

- Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning

- Durable: Lower operating rpm means rotating parts last longer

- Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners

- Sturdily construction: Made of 316 stainless steel. Non-contact parts and attachments in 304 stainless steel and chrome

Pusher Centrifuge

B&P Littleford's Pusher Centrifuges (liquid-solid separation centrifuges) relentlessly separate coarse solids from free-draining crystalline slurries in the most extreme conditions. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering, and top-grade construction.

Pusher Centrifuges are developed and manufactured for standard products but can be customized for special or difficult solid separation applications.

B&P Littleford Pusher Centrifuges feature:

- Single-piece reversible wedge-slot screen that efficiently separates solids and liquids

- Screen supported by a centrifugally cast, milled-slot cage basket

- Heavy-duty bearings carry the main hollow shaft, which drives the basket

- Belt-driven hydraulic pump for energy efficiency, safety and reliability

- Internal, self-contained hydraulic piston driving the pusher shaft

- Rugged base provides rigid support for the entire rotating assembly

- Cooling coils that maintain the hydraulic system temperature at optimum levels

Delivering the service you need

B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal & vertical centrifugal separation equipment for many different manufacturing applications.

- More than 100 years’ industry experience

- Quality products built to last

- Responsive service and support

- Professional, knowledgeable staff

- Top-notch testing facilities

Pod Centrifuge

B&P’s Podbielniak® Contactor (POD®) is a horizontal axis centrifuge that processes liquids in solvent extraction.

Liquid Liquid Extraction

Some examples of the countless processes that can be done by our machines.

Pusher Centrifuge

B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries.

Liquid Solid Separation

Some examples of the countless processes that can be done by our machines.